Heavy equipment—such as excavators, loaders, cranes, and trucks—is the backbone of industries like construction, mining and logistics. These machines are capital-intensive and downtime-sensitive. Ensuring that they run reliably means not only using the right spare parts but also adopting a robust preventive maintenance program. In 2025, industry-leaders increasingly view spare parts and maintenance as strategic assets rather than only cost centres.

When heavy equipment fails unexpectedly, the consequences go beyond repair bills: labour delays, missed project milestones, and cascading operational disruptions. By combining quality spare parts sourcing with scheduled preventive maintenance, companies can shift from reactive repair to proactive reliability and significantly improve machine availability and operational safety.

Importance

Spare parts management and preventive maintenance are intertwined for several reasons:

-

Reliable machines use the right parts at the right time; using sub-standard parts or delaying replacements weakens reliability.

-

Preventive maintenance (PM) reduces unplanned downtime and major repair costs by identifying wear and consuming parts before failure.

-

Strong parts and maintenance practice extend service life, protect resale value, and support safety and regulatory compliance.

These factors make spare-parts strategy and maintenance scheduling key to cost-control and asset-performance optimisation.

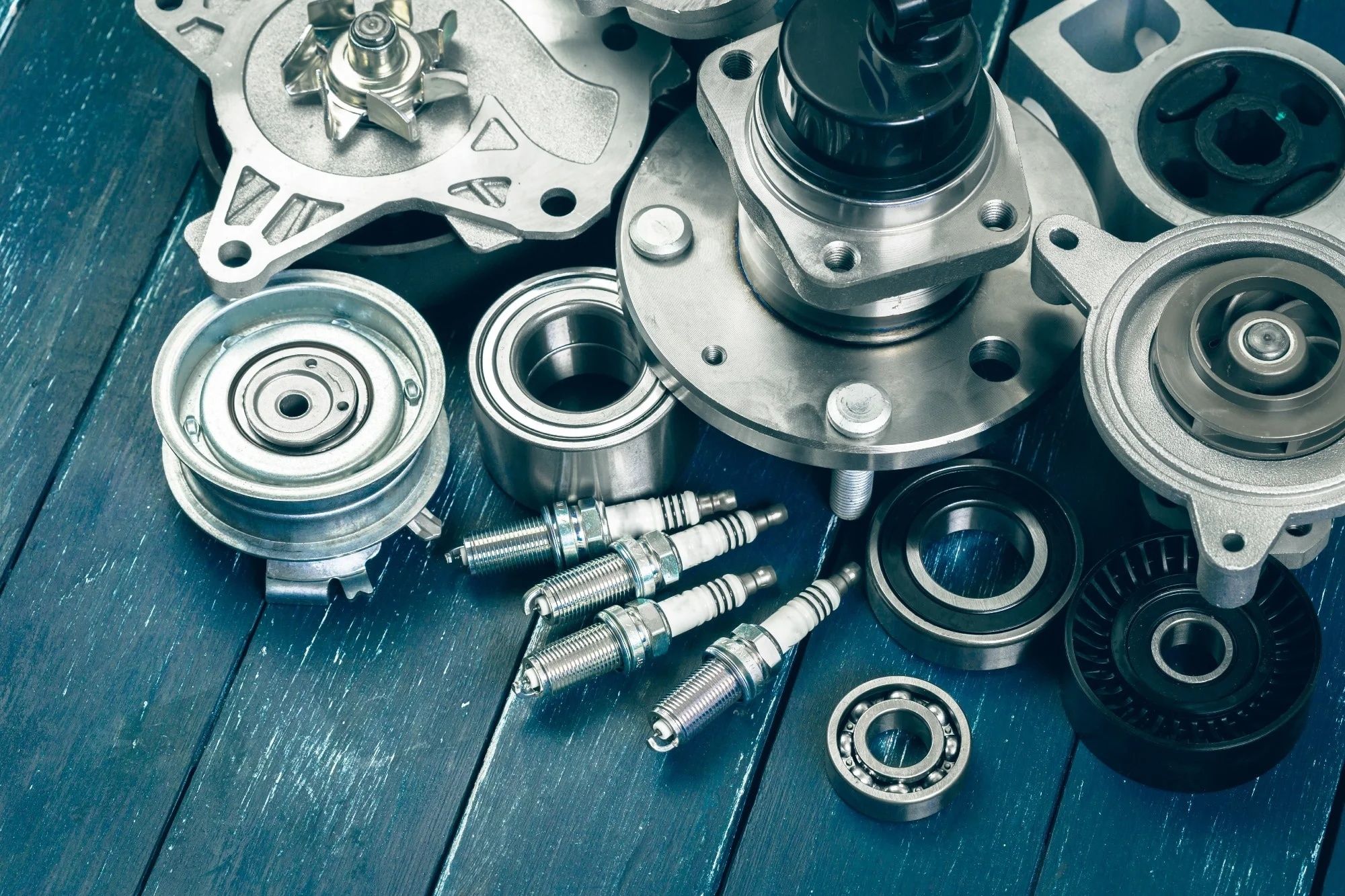

Key Components of Spare Parts Management

When dealing with heavy equipment spare parts, consider the following:

-

Consumable parts versus integral parts: Consumables include filters, belts, fluids, pins, bushes—parts that require frequent replacement. Integral parts are major assemblies or components (engine, hydraulics, drivetrain) whose failure causes significant downtime.

Quality and origin: OEM (Original Equipment Manufacturer) parts often cost more but provide better fit, warranty and reliability. After-market or rebuilt parts may be cheaper but need robust evaluation.

-

Inventory and logistics: Keeping critical parts on-hand reduces repair lead time. Effective parts-management correlates with lower mean down time.

-

Usage-based forecasting: Instead of simply replacing based on calendar time, parts replacement should consider hours of operation, load conditions and historical wear patterns.

Preventive Maintenance Strategy

Preventive maintenance for heavy equipment involves scheduled tasks aimed at preventing failures rather than reacting to them. Key practices include:

-

Daily or pre-shift inspection: check fluids, batteries, tyres/tracks, visual leaks or damage.

-

Monthly or usage-based servicing: replace filters, inspect hydraulics, check electrical wiring and attachments.

-

Annual or major-service overhaul: engine tune-up, structural inspections, full system diagnostics.

-

Data-driven scheduling: using historic failure data and condition monitoring to adjust the PM cadence, avoiding both over-maintenance and under-maintenance.

Benefits of Effective Spare Part and PM Program

-

Reduced unexpected downtime and emergency repairs.

-

Extended machine lifespan and maximised return on investment.

-

Lower operating cost per machine hour.

-

Improved safety and regulatory compliance.

-

Better productivity and reliability across project timelines.

How to Choose Spare Parts & Maintenance Tools

-

Match parts to equipment make and model—double-check compatibility.

-

Evaluate cost versus life-expectancy of parts (cheaper today may cost more in downtime).

-

Choose maintenance tool-sets: checklists, CMMS (Computerised Maintenance Management Systems) to manage parts, tasks and history.

-

Train operators and technicians: a well-trained workforce catches issues early and uses parts correctly.

-

Monitor key indicators such as planned vs reactive maintenance ratio, repeat failures, downtime hours.

FAQs

Q1. What is the difference between preventive and predictive maintenance?

Preventive maintenance is scheduled at fixed intervals (time or usage based). Predictive uses condition-monitoring (sensors, analytics) to perform maintenance when data indicates it’s needed.

Q2. How often should heavy equipment spare parts be inspected or replaced?

It depends on usage, operating conditions, and manufacturer guidance. Critical parts may need inspection or replacement every few hundred machine-hours; consumables more frequently.

Q3. Why is OEM parts quality so important?

Because integral components that fail can cause cascading damage, using genuine, compatible parts protects machine integrity and warranty.

Q4. Can small fleets benefit from preventive maintenance programs?

Yes—regardless of size, structured PM reduces downtime and costs. Even smaller operators benefit by standardising inspections, parts inventory and scheduling.

Q5. How much savings does preventive maintenance deliver?

Studies show preventive maintenance can reduce downtime by over 50% and cut repair costs by 25-40%.

Conclusion

Managing spare parts and preventive maintenance for heavy equipment is not simply a service cost—it’s a strategic investment in reliability, productivity and asset longevity. By combining quality parts sourcing with planned maintenance schedules, organisations can move from reactive firefighting to proactive control. The result: machines that run longer, projects that stay on schedule and businesses that perform stronger in competitive environments.